"Government Recognised Star Export House"

"Government Recognised Star Export House"

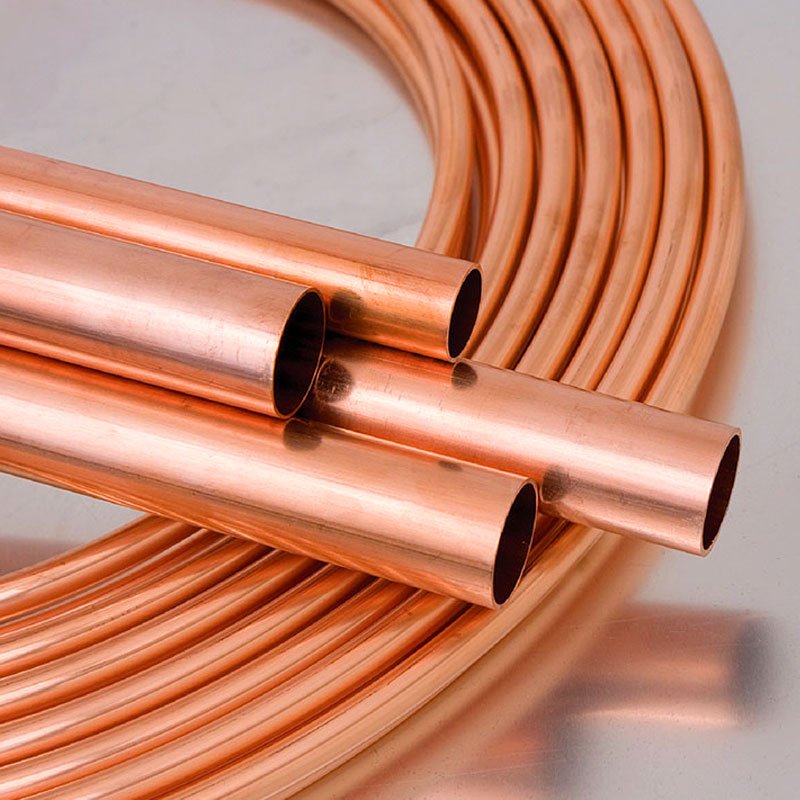

India's Trusted Manufacturer & Suppliers of Electrical Cable

Accessories, Earthing & Lightning

Protection, Cable Jointing

& Termination Kit Components and Copper Braids .

+91 22 6659 5027

sales@nexuscopper.com